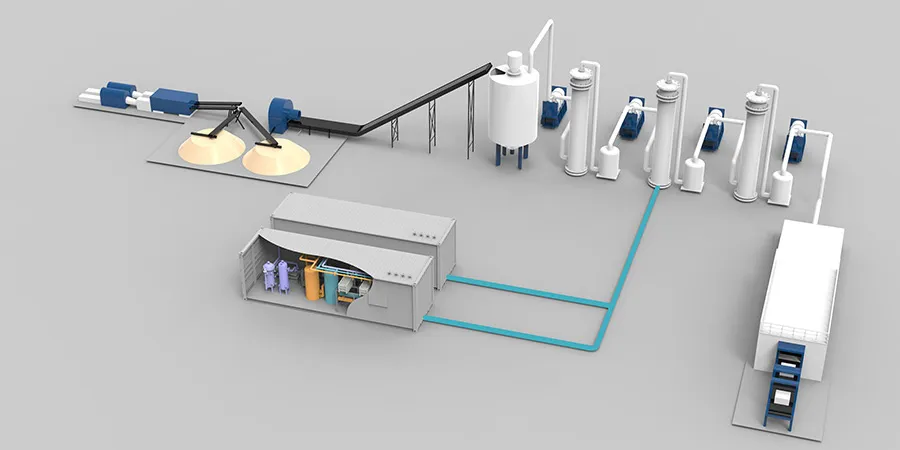

Crofton Mill is situated in the Cowichan Valley on Vancouver Island and commenced operations in 1957. Currently, it houses two paper machines and two pulp production lines. The mill employs the latest production technologies, is committed to environmental sustainability, and has reduced greenhouse gas emissions by 66% since 1990.

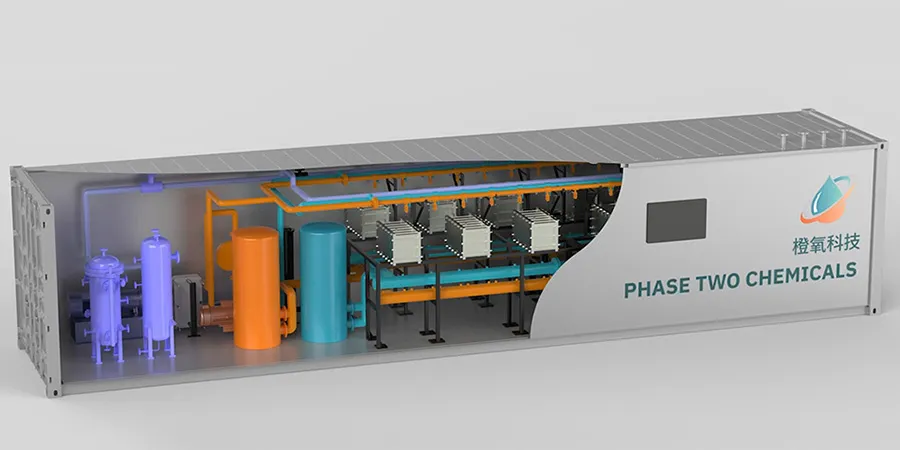

In pursuit of a more effective bleaching agent production solution and to further cut carbon emissions, Crofton Mill has partnered with Phase Two Chemicals. Our company completed the manufacturing of the first electrochemical hydrogen peroxide production system in 2021, and the system was put into operation in April 2022. A single system has a daily production capacity of up to 1.3 tons (equivalent to 100% concentration). In response to the customer's request, a technical upgrade was conducted in 2024. Two new sets of P1528 electrochemical hydrogen peroxide production systems were added, each with a daily output of 1.5 tons, to replace the original systems.

Phase Two Chemicals is dedicated to promoting the wide application of green technologies in other potential industries under the "dual carbon" (carbon peaking and carbon neutrality) context. We are willing to discuss various feasible cooperation models with customers to jointly achieve this goal.