Alkaline hydrogen peroxide electrolytic generation system provides a more environmentally friendly, efficient, and safe choice for chemical pulp processes.

Chemical pulping is a process that involves using fiber plants (such as wood and straw) as raw materials, along with a specific chemical agent. The chemical agents react selectively with the lignin present in the raw materials to remove most of the lignin and make the single fibers of materials to be fully separated into pulp.

Common chemical pulp classification:- Kraft Pulp (Sulfate Pulping)

- Neutral Sulfite Semichemical Pulp

- Sulfite Pulping

- Alkaline Peroxide Pulp

- Soda Pulping (Sodium Hydroxide Pulping)

- Chlorine-Free Pulping

- Oxygen Delignification

The produced pulp usually has a higher purity of cellulose, not only providing high-purity cellulose pulp but also a reliable source of raw materials for paper production.

Traditional bleaching processes can use chemical agents, but this method may produce wastewater and exhaust gas emissions that have an impact on the environment. If hydrogen peroxide is used for bleaching, additional hydrogen peroxide delivery vehicles, personnel, and hydrogen peroxide storage systems are required.

Using chemical reagents and high-concentration hydrogen peroxide may cause fiber loss, significantly reducing the quality of paper products for papermaking industry.

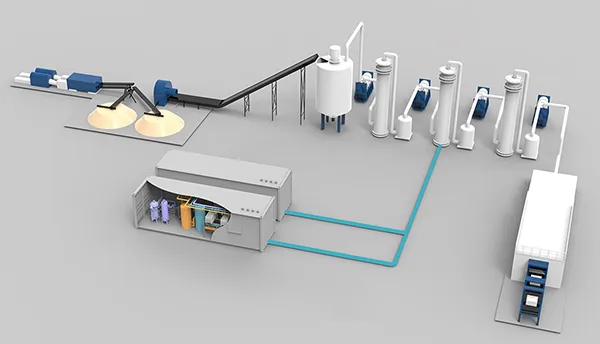

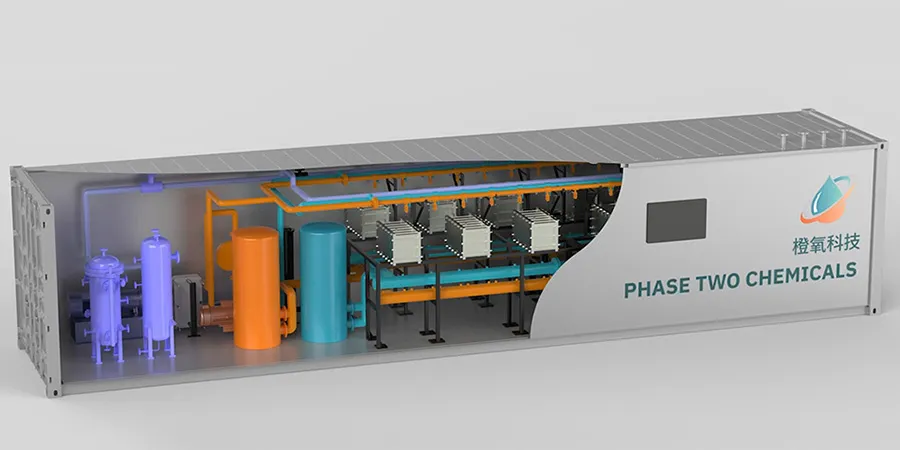

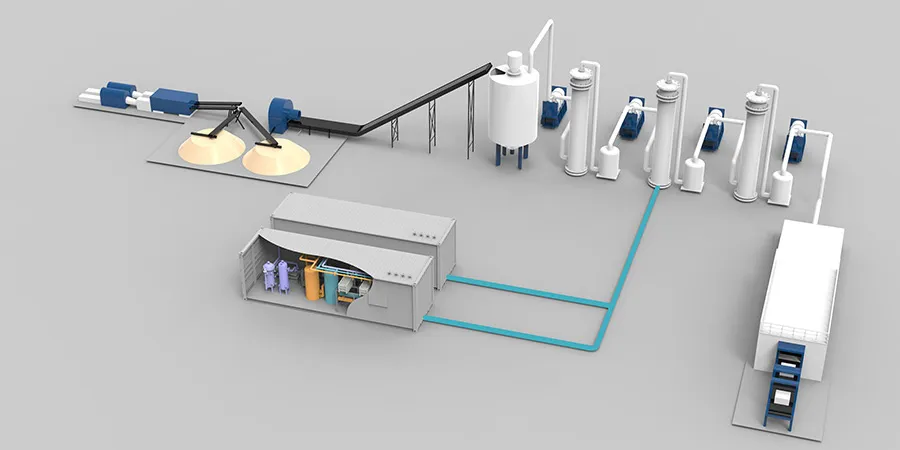

Our alkaline hydrogen peroxide electrolytic generation equipment only needs oxygen, hydrogen, and electricity to achieve continuous production of hydrogen peroxide, with no pollutants and effectively reduced carbon emissions, achieving both environmental protection and economic benefits.

In the EOP process of chemical pulping, the low-concentration hydrogen peroxide (2%~5%) produced by our electrochemical on-site generation system completely replaces traditional high-concentration hydrogen peroxide (27.5%~70%), providing a more environmentally friendly and efficient option.